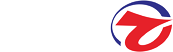

Mold Design Information

Mold design is a rigorous work, don't cause serious consequences because of your mistakes.

Now I tell you how to design this mold,

Customer:Germany

Design software: NX (UG)

Design time: 12day

Part Material: PP

Part Size L*W*H(mm): 198 X 195 X 225mm/192 X 239 X 117mm

Part Weight: 300g /200g

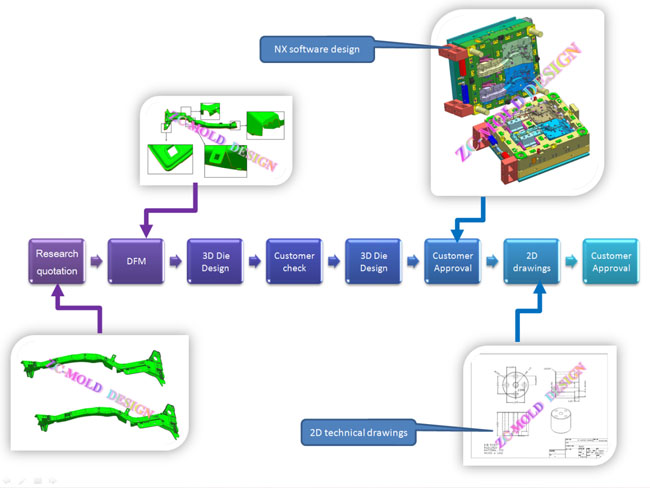

No. of Cavities: 1+1

No. of Sliders: 7

Structure: 2-plate

Injection machine: 1000T

Mold Size(mm): 800.00 X 1100.00 X 1096.00mm

Hot Runner (Valve),

Two-stage ejection

NX UG Face Analysis

We use NX UG Face Analysis, obviously, the blue face is undercut, so we need to do the sliders.

One of the slider structures is more complicated.It needs a large slider to move with a small slider.

Slider structure analysis

As shown in the picture below, there are many undercuts in this part, and the direction of release of each undercut is different. The red arrow is the direction of release.

As shown in the picture, for better identification, we call these parts A,B,C,D,E,F,

The inside small slide block will recede first and the parent slide block have to postpone Sliding

1.The function of the positioning block(F) is to make the slider(E) not move first.

2.The green slider moves(D) to the back,At the same time, 3 small slider(A,B,C) move inward.

3.The positioning block can be moved, when the green slider moves(D) moves to the distance we designed,it will move with the slider(E).