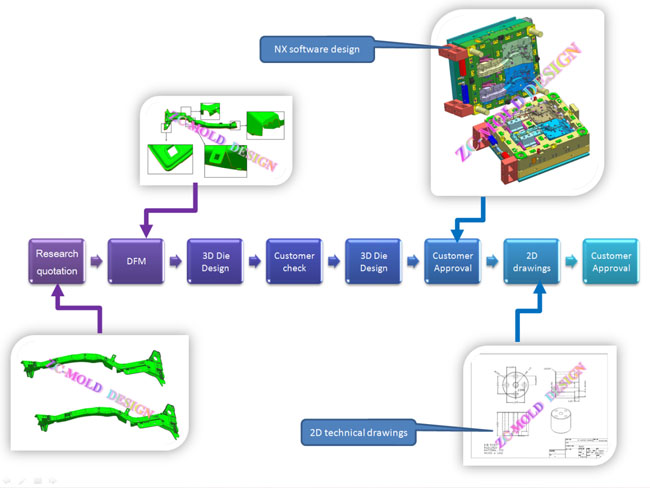

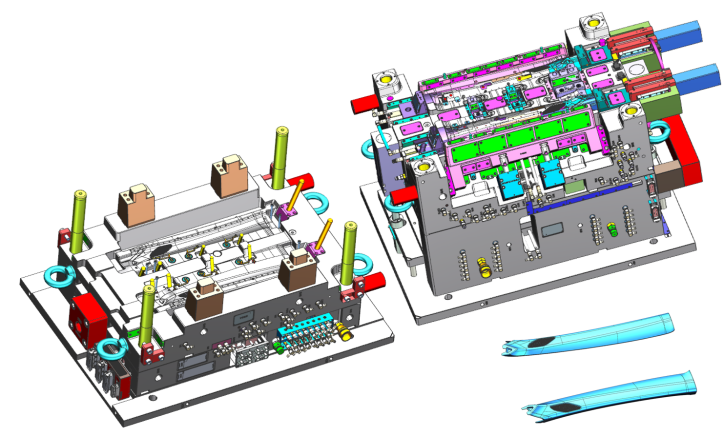

1.Determine Mold Opening Direction

During the parting plane design stage, the designer need determine mold opening direction. Usually the visible surface is in the cavity side, and the ejector system is on the core side.

It may appear that there is nothing about the mold opening direction to determine since the mold opens normal to the parting plane. However, it is necessary to determine the mold opening direction relative to the mold cavity and direction of part ejection. There are two factors that govern the mold opening direction.

1.The mold cavity should be positioned such that it does not exert undue stress on the injection mold. The mold cavity is typically placed with its largest area parallel to the parting plane. This arrangement allows the mold plates, already being held in compression under the clamp tonnage, to resist the force exerted by the plastic on the surfaces of the mold cavity.

2.When we design some more complex molds, we need to consider how many slider structures, how can we determine mold opening direction to make the mold simple and the mold smaller to fit the injection molding machine and save production costs.

2.Parting Plane Design

The parting plane is the contact surface between the stationary and moving sides of the mold. The primary purpose of the parting plane is to tightly seal the cavity of the mold and prevent melt leakage. This seal is maintained through the application of literally tons of force (hence the term “clamp tonnage”) that are applied normal to the parting plane. While the term “parting plane” implies a flat or planar surface, the parting plane may contain out-of-plane features. Prior to determining the parting line and designing the parting plane, the mold designer must first determine the mold opening direction.

Once the parting line is identified, the parting plane is projected outwards from the part so as to separate the core insert from the cavity insert. If the mold opening direction is the direction of the Z axis, we often extend the surface in the X Y direction according to the parting line, but we need to consider the release direction of the slider. The slider release direction and parting plane are different, when the slider is open, it may hit the cavity side.There are undercut on the red surface by slider release direction as show.

3.Mold sharp steel

The last thing we want is to have sharp steel in the mold. This is not only difficult to fit mold, but also affects the service life of the mold. The included angle of the parting plane in the first picture is less than 70 degrees. We need to press the second picture. The included angle is greater than 70 degrees.

4.Shut-Offs

Interlocking features on the parting plane should be inclined at least five degrees relative to the mold opening direction. Sometimes, for relatively high part, when the parting line shut off angles are to be 2 degrees, we need to confirm with customer whether it is acceptable.

We will create 4 interlocks to protect the shut off surface. 3 deg. core and cavity with 0 .0015” gap between locks. This angle can be decreased to protect shutoffs as required.

5.Parting plane interlock

When the mold is produced by injection molding,to avoid excessive stress, cause the cavity side and core side to be separated.

Figure 1 The design of this picture is wrong. The interlock is on the same side. When the injection pressure is high, the cavity side and the core side will be separated toward the red arrow.

Figure 2 This picture design is correct, make an interlock on the cavity side and core side. In this way, the design can avoid excessive stress. Cause the cavity side and core side are separated.

6.CNC machined

We ear know these parting plane may be directly machined using computer numerically controlled (CNC) machining or via plunge electrical discharge machining (EDM)using one or more electrodes that were CNC machined. But we like CNC machining and reduce EDM machining, which can improve efficiency and save costs, so we will change the parting plane to achieve CNC machining.

At the location of the arrow in the picture below, in the second picture we can create a pocket so that the CNC can machine it.

We are creating the parting plane, to see if it can be machined by CNC,The machining depth of the milling cutter is 5 times the diameter of the milling cutter,The R of the mold is larger than the diameter of the milling cutter.If the R of the pocket is the same as the diameter of the milling cutter, the milling cutter will swing during machining and cause machining errors.

7.Parting plane design requirements

1.To avoid excessive stress, interlocking features on the parting plane should be inclined at least five degrees relative to the mold opening direction.

2.These surfaces may be directly machined using computer numerically controlled (CNC) machining.

3.All sides and radii not shutting off must be cleared.

4.Verify that required cutter size will cut pocket correctly at corner.

5.Design pocket with drilled corners whenever possible to avoid adding radii to inserts.

Whenever using a cutter in a corner, use 60% of tool diameter for corner radius. Example: if using a 0.500” diameter cutter, do not use a 0.250” corner radius, use a 0.300” corner radius.