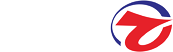

1. DFM can better assist you in mold design

After the customer agrees to the order, don't rush to use 3D software for mold design.

We need to ensure that the part used is the final version. Whether the customer needs us to provide DFM, DFM means mold design analysis report.

For example, the information of DFM includes (Parting line, gate location and size, slide lines, The analysis of draft, The analysis of sink marks, Geometry suggestion, Engraving and aspect, Ejector line, Mold layout, Injection machine) This information is more critical and we need to confirm with the customer.

2. Understand customer mold design standards

We all know that each customer's design standards are different. First, we check whether we have designed the mold design of this customer before. If we have designed this customer's mold design before, we can follow it.

But I think every mold maker has mold design standards. We can design according to the mold design standard he provided us.

3. Shrinkage is about the success or failure of your design

After the plastic enters the mold and begins to cool, part will start to shrink. So the mold size is a little larger than the actual part size. Every plastic shrinks differently. Shrinkage is very important.Changing the shrinkage of the mold design is a hassle if you get the shrinkage wrong. When the mold is complete, forget the shrinkage in your design. This is a very serious mold design error, so guys don't forget it.

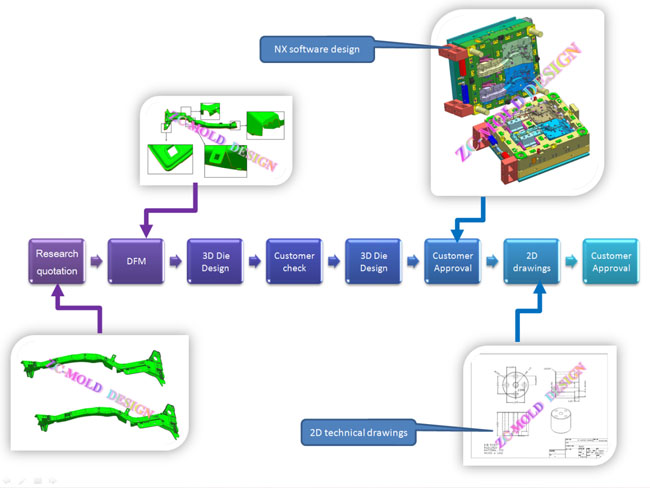

4. How to improve the efficiency of mold design

When you know how to do something, you will do it quickly, and the same is true for mold design. When you want to design the mold, you can think about how to create the cavity and core, how to design the slide, lifter, ejection system, etc. If you have a good idea, you can complete it quickly.

5. Injection molding machine size is critical to mold design

We ultimately use the injection molding machine for mass production products. The size of the mold determines of the injection molding machine. Sometimes we have to design the mold according to the size of the injection molding machine provided by the customer. All mold design details must meet the injection molding machine.

For example, whether the mold can be put into the injection molding machine normally,Is the Locating Ring, Nozzle radius, KO position correct?