In-Depth Guide to Injection Mold Manufacturing: Processes, Technologies, and Applications

Injection mold manufacturing is a cornerstone of modern mass production, enabling the creation of complex plastic components with unmatched precision and efficiency. This comprehensive guide explores every facet of injection mold manufacturing, from design principles to cutting-edge innovations.

1. What is Injection Mold Manufacturing?

Injection mold manufacturing involves creating custom-designed tools (molds) used to produce plastic parts through the injection molding process. These precision-engineered molds:

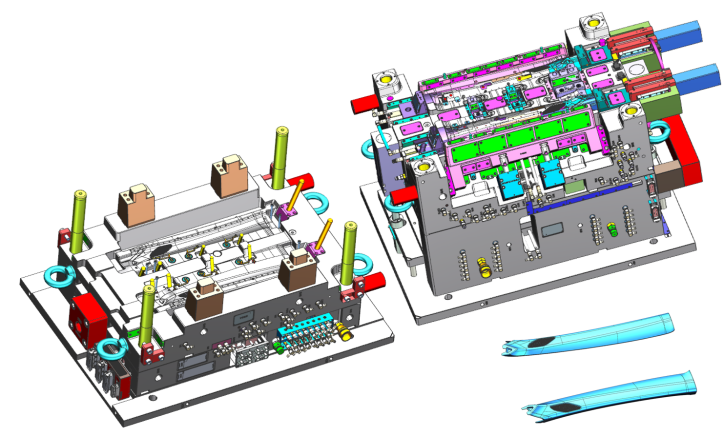

Consist of two halves (core and cavity)

Are typically made from hardened steel or aluminum

Contain intricate channels for molten plastic flow and cooling

Determine final part geometry, surface finish, and dimensional accuracy

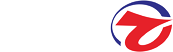

2. The Injection Mold Manufacturing Process: Step-by-Step

Phase 1: Product Design Analysis

DFM (Design for Manufacturability) review

Wall thickness optimization

Draft angle verification (typically 1-3°)

Undercut and ejection system planning

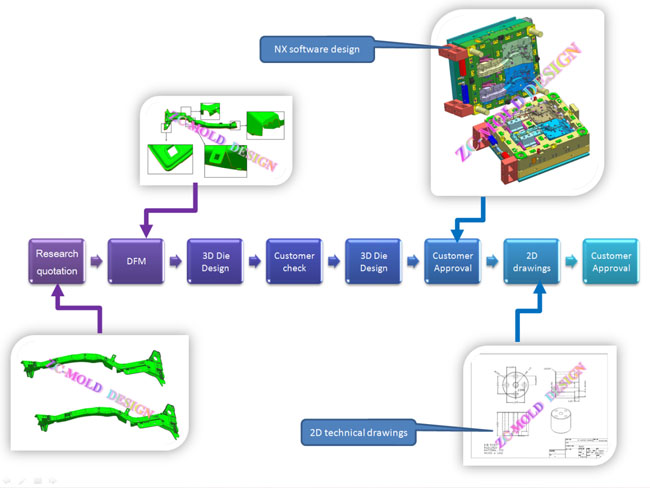

Phase 2: Mold Design Engineering

3D CAD modeling (SolidWorks, UG NX)

Gate type selection (edge, submarine, hot runner)

Cooling system simulation (Moldflow analysis)

Ejection mechanism design (pins, sleeves, stripper plates)

Phase 3: Precision Manufacturing

| Process | Technology | Tolerance |

|---|---|---|

| CNC Machining | 5-axis milling, EDM | ±0.005 mm |

| Heat Treatment | Vacuum hardening (HRC 48-52) | - |

| Surface Finishing | Texturing (VDI 3400 standard) | Ra 0.1-1.6μm |

| Assembly | Guided ejection, alignment systems | ±0.01 mm |

Phase 4: Testing & Validation

T0 Sample Inspection (first-shot parts)

Dimensional checks with CMM

Cycle time optimization

Mold flow analysis verification

3. Advanced Technologies in Modern Mold Making

A. Smart Mold Systems

Embedded sensors for real-time monitoring

IoT-enabled pressure/temperature controls

Self-lubricating components

B. Hybrid Manufacturing

3D printed conformal cooling channels

Laser-cladded wear-resistant surfaces

Micro-milling for optical-grade cavities

C. Sustainable Practices

Recycled tool steel utilization

Energy-efficient mold heating systems

Closed-loop cooling water circuits

4. Material Selection Guide

| Material | Best For | Lifespan (cycles) | Cost Factor |

|---|---|---|---|

| P20 Steel | Prototypes, low volume | 50,000-100,000 | |

| H13 Tool Steel | High-volume production | 1,000,000+ | |

| Aluminum 7075 | Rapid tooling | 10,000-50,000 | |

| Beryllium Copper | High thermal conductivity | 500,000+ |

5. Industry-Specific Applications

Automotive:

LED headlight housings (PMMA molds)

Engine intake manifolds (gas-assisted)

Dashboard components (multi-material molds)

Medical:

IV connectors (Class 101 molds)

Surgical instruments (micro-molding)

Implant packaging (clean room compliant)

Consumer Electronics:

Smartphone casings (mirror-finish cavities)

Waterproof connectors (overmolding)

Thin-wall battery covers (<0.5mm)